AN ENGINEERING MARVEL

QE2 was not the largest liner ever built, nor was it the fastest, those honors went to the France and the United States respectively. None the less, she had all the latest technology the age had to offer. She was assembled at the ship yards of the John Brown & Company of Glasgow, who built liners for Cunard as far back as 1900 with the 14,200 ton Saxonia. Their long history, which included both the Queens Mary and Elizabeth may have been a plus, but in undertaking the Q4 project, most of the formulas that had worked so well over the years would have to be disregarded for an all new interpretation of the passenger liner. Unlike here predecessors, QE2 would have a dual function: the traditional north Atlantic run during the summer; a one class, warm weather cruise ship during the winter.

Cut-away profile illustrations have always been popular way for ship owners to publicize their newest ships. From a 1969 Daily Telegraph feature, the following statistics were touted:

|

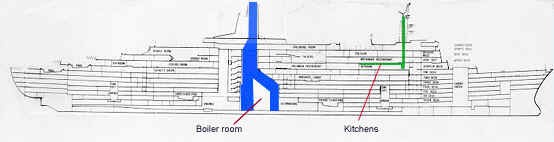

| When looking at QE2 most would think that she has only one funnel. But in fact, she has two. In the cross section above, blue shows that the gasses from the engine and boiler rooms are vented out of the large funnel just aft of midship. The kitchens are vented through their own duct work hidden in the forward mast, highlighted green. |

One of the most ingenious innovations on QE2 concerned her main funnel. From the earliest

days of steam ship travel, a persisting dilemma was exhaust from the stack drifting over

the after open deck space. The soot and fumes annoyed passengers, dirtied their clothes

and irritated the eyes, making the only large open area unpleasant. On QE2 the problem

would have been magnified because the entire area was to be enclosed with tall

windscreens. While protecting the two out door pools and sun decks from the stiff ocean

breeze it would give the fumes little place to escape. Using models in a wind tunnel, many

studies were done (right)and the solution came in the form of the windscoop at the base of

the funnel. As the ship moved forward, air is channeled up the scoop and helps push the

exhaust fumes up and away to clear the decks(below left). This action was represented in a

rather fanciful illustration (below right) by Wolf Sporel.

One of the most ingenious innovations on QE2 concerned her main funnel. From the earliest

days of steam ship travel, a persisting dilemma was exhaust from the stack drifting over

the after open deck space. The soot and fumes annoyed passengers, dirtied their clothes

and irritated the eyes, making the only large open area unpleasant. On QE2 the problem

would have been magnified because the entire area was to be enclosed with tall

windscreens. While protecting the two out door pools and sun decks from the stiff ocean

breeze it would give the fumes little place to escape. Using models in a wind tunnel, many

studies were done (right)and the solution came in the form of the windscoop at the base of

the funnel. As the ship moved forward, air is channeled up the scoop and helps push the

exhaust fumes up and away to clear the decks(below left). This action was represented in a

rather fanciful illustration (below right) by Wolf Sporel.

|

|

Another long time problem was the tendency for a ship to roll in heavy seas. Stories of

crossings where every passenger became so sea sick that meal after meal went untouched are

abundant. To help combat this predicament QE2 is equipped with four gyro-controlled

stabilizers under the water line. Acting like the wing flaps on an airplane the

stabilizers pivot to reduce a 20 degree roll to an unnoticeable three degrees. The foils

are stowed by swinging forward into the hull, important when traveling through the Panama

Canal which QE2 barely clears. The stabilizers are hardly new technology, the Queen Mary

had four installed in the 1950's. QE2 also has two 100hp bow thrusters, new for a trans

Atlantic liner, but common on todays smaller cruise ships.

Another long time problem was the tendency for a ship to roll in heavy seas. Stories of

crossings where every passenger became so sea sick that meal after meal went untouched are

abundant. To help combat this predicament QE2 is equipped with four gyro-controlled

stabilizers under the water line. Acting like the wing flaps on an airplane the

stabilizers pivot to reduce a 20 degree roll to an unnoticeable three degrees. The foils

are stowed by swinging forward into the hull, important when traveling through the Panama

Canal which QE2 barely clears. The stabilizers are hardly new technology, the Queen Mary

had four installed in the 1950's. QE2 also has two 100hp bow thrusters, new for a trans

Atlantic liner, but common on todays smaller cruise ships.